Yamahai・yama-oroshi-haishi-moto

- 【English】

- Yamahai; yamahai yeast starter

- 【Japanese】

- 山廃・山卸廃止酛

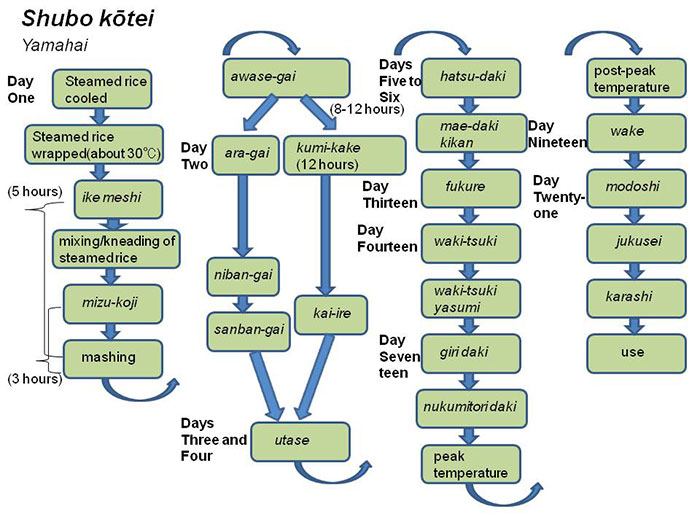

A method invented by Kagi (嘉儀) et al in 1909. A derivation of kimoto in which the moto suri (“grinding the moto”) stage is omitted. (Moto suri is also called yama-oroshi, and omission is haishi (廃止). Yamahai combines the first character of both, so literally means “omission (or cessation) of yama-oroshi”.) In the kimoto method, yama-oroshi is the process of grinding the raw materials ten to twelve hours after they have been mashed in a number of hangiri tubs. This is done either with a round-headed kai tool (called kabura-gai “, “turnip kai”) or by “treading” the mash. In the former case, it is known as ara-zuri (rough grinding)、in the latter ara-bumi (rough treading). The process is repeated twice at four-hour intervals, tasks known respectively as niban-zuri (second grinding) and sanban-zuri (third grinding). Although it varies with the hardness of the steamed rice, grinding is usually complete after three sessions. This laborious work was carried out in three-man teams singing special moto-grinding songs in order to keep a common rhythm and measure the time spent at the task.

When making yamahai, hangiri tubs are not used. Mizu-koji is made in a single vessel, and steamed rice treated largely the same as for kimoto completes the mash. Unlike kimoto, kai-ire or kumi-kake (circulating the liquid of the mash by filtering it through a cylinder placed in the centre, and ladling the accumulated liquid over the mash outside the cylinder) are carried out in place of yama-oroshi.

Compared to kimoto, the yamahai method offers great savings in the space and labour necessary. In the Nada area, it was widely used as an abbreviated version of the original kimoto. In recent years, the number of firms using the yamahai method declined for labour-saving reasons at one stage, but there has been an increase of late.