Sei-kiku・sei-kiku kōtei

- 【English】

- Kōji making; kōji- making process(es)

- 【Japanese】

- 製麹・製麹工程

The process of production of koji for seishu is properly known as sei-kiku (製麹). The various systems used include the classical method using small tray-like futa boxes “tray” koji (futa-koji-ho (long “o”s)), the “box” method (hako-koji-ho), which uses slightly larger boxes than the classical method in order to economize on space and labour, the “bed” method (toko-koji -ho), which dispenses with boxes entirely and sees the entire process carries out on a large bed (toko) , and machine-made koji (kikai-sei-kiku-ho), in which last temperature, humidity and growth condition are all controlled automatically. (The rules of Japanese pronunciation mean that futa and hako become voiced in compound words, so futa becomes koji-buta, and hako becomes koji-bako in compound.)

All the methods share the following common preliminary processes.

Raw material (rice) → rice polishing → soaking → steaming → cooling steamed rice. From this point on, koji making proper begins.

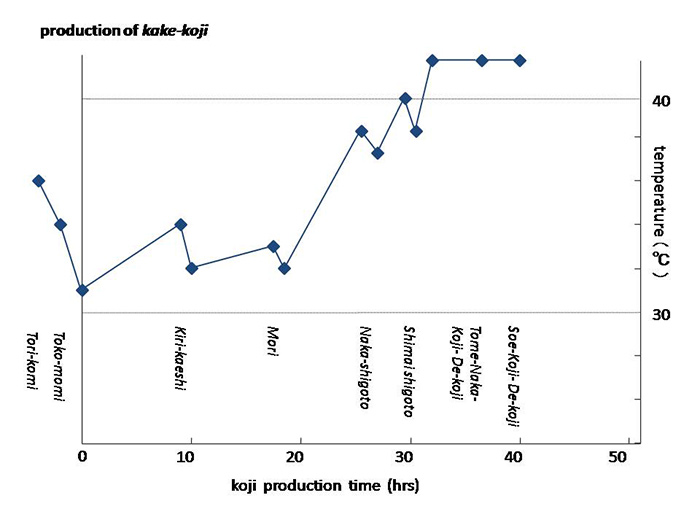

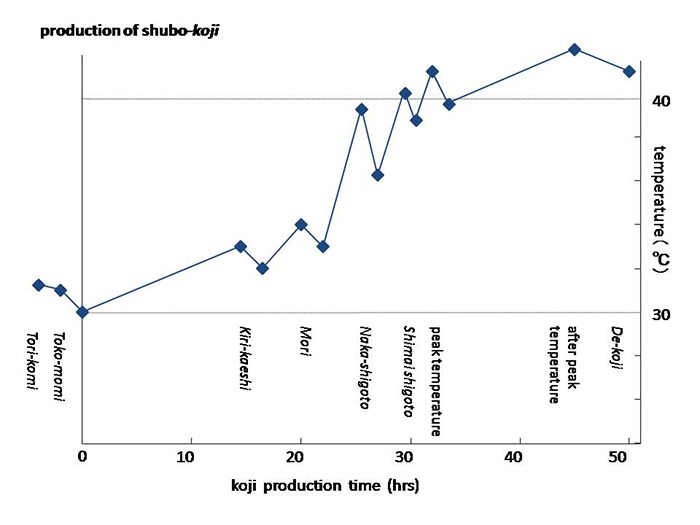

- Tori-komi (取込み, hiki-komi (引込み))

Cooled steamed rice is taken into the culture room, and piled up on a flat

toko table at about 33 – 36°C. - Toko-momi (床揉み)

Three or four hours later, the steamed rice is spread out again, and tane-koji is sprinkled on (tane kiri, 種切り). The temperature after this stage is about 30°C. - Kiri-kaeshi (切返し)

After a further twelve to sixteen hours, the pile is broken down and mixed to even out temperature and moisture content. - Mori (盛り)

This is the process of dividing the batch into small lots into futa trays or boxes (or making a thin layer on a toko bed or machine where such are used) after points of haze have become visible on the grains. - Naka-shigoto (first mixing) 仲仕事

Six to eight hours after mori, when the temperature of the koji has reached about 34 – 36°C, it is mixed well to disperse moisture and promote oxygen supply. - Shimai shigoto (second mixing) 仕舞仕事

Five to seven hours after the first mixing, when the temperature has reached 37 – 40°C, the batch is mixed once more, and spread out to ventilate and cool it. After this stage, the particular batch reaches its highest temperature (saiko ondo (long first ”o”), 最高温度). - De-koji 出麹

The end of the sei-kiku process is decided by appearance, aroma and so on. The finished batch is cooled in the cold air outside the culture room, thereby stopping the growth of the koji -kin. It is usual to take a conditioning period (karashi, 枯らし) and use the finished koji in mashing the following day. If it is used on the same day as de-koji, this is known as de-zukai (出使い). As a process, the action of using the koji in mashing is simply called shiyou (使用), use.

torikomi

tokomomi

mori 1

koji-bako

mori 2